Applications:

EV/Energy: SiC power modules for fast chargers & inverters

Aerospace: Oxidation-resistant coatings for turbine components

Semiconductor: Wafer carriers and diffusion fixtures

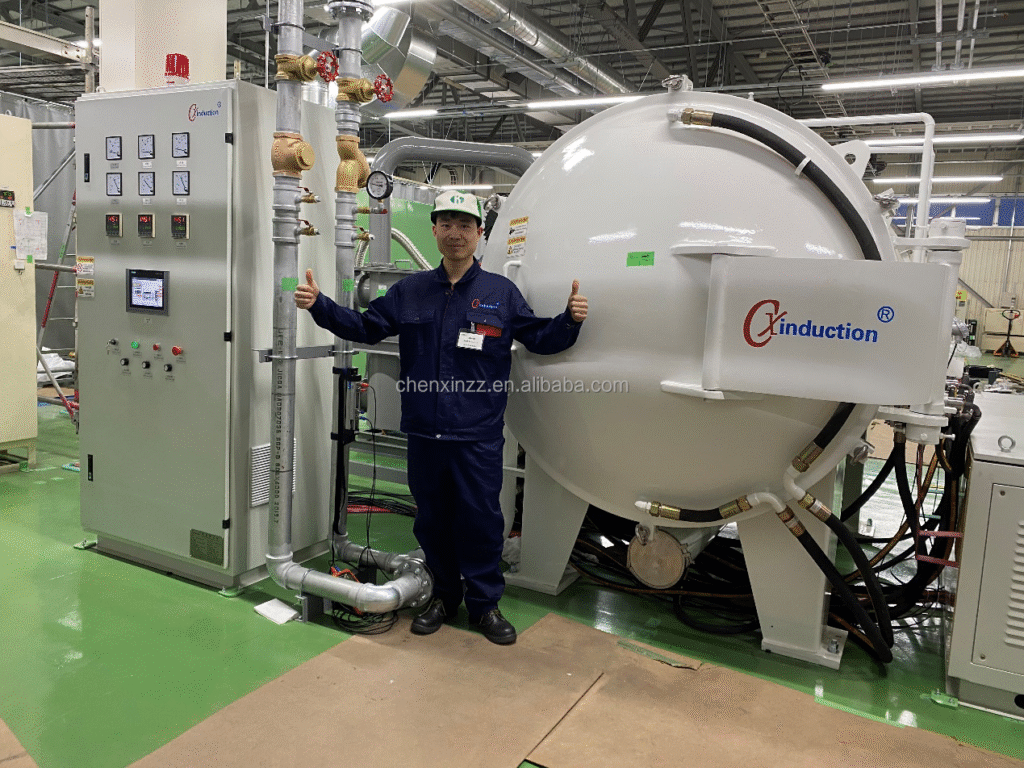

Advanced CVD Solutions for SiC Semiconductor Manufacturing

Cxinduction™ presents a 1600℃ Multi-Atmosphere CVD Furnace specifically engineered for high-quality SiC epitaxial growth and advanced material coatings. Our horizontal hot-wall CVD system delivers superior uniformity and repeatability for:

✔ SiC Power Devices: Epitaxial wafers for MOSFETs/Schottky diodes (4H-SiC & 6H-SiC)

✔ High-Temp Components: Coating of crucibles, susceptors, and CMC materials

✔ Wide-Bandgap Semiconductors: BN and doped-SiC deposition

Key System Advantages

Graphite Muffle Design: Ensures contamination-free processing and excellent temperature uniformity (±2℃ at 1600℃)

Precise Process Control:

Multi-gas atmosphere with mass flow controllers

Constant-pressure mode (10-2Pa~100 kPa) for stable epitaxial growth

End Applications:

EV/Energy: SiC power modules for fast chargers & inverters

Aerospace: Oxidation-resistant coatings for turbine components

Semiconductor: Wafer carriers and diffusion fixtures

Parameters:

Model | CX-CVD40/SIC | CX-CVD50/SIC | CX-CVD60/SIC | CX-CVD60I/SIC |

Heating Method | Graphite Resistance | |||

Control Method | Auto & MAN | |||

Max Work Temp | 1600℃ (1800℃ optional) | |||

Rated power | 70KW | 85 KW | 120 KW | 160 KW |

Usable Space (mm) W*H*L | 400×400×1200 | 500×500×1500 | 600×600×1800 | 600×600×2000 |

Max. Loading Capacity (L) | 192L | 375L | 648L | 720L |

Temp Uniformity | ±2℃ (ΔT between 1000C and 2200C) | |||

Max. Heat-up Rate (CEDRT)* | 15℃/min | |||

Ultimate Vacuum (CEDRT)* | 1.2×10-3mbar | |||

Optional High Vacuum (CEDRT)* | 5×10-5mbar | |||

Pressure Rise | 1.33×10-2mbar/hr | |||

Working Atmosphere | Fine Vacuum (Optional) / Vacuum / Inert Gas (Ar or N2) | |||

Supply Voltage | Can be customized | |||

Cooling Water Pressure | 2bar | |||

Cooling water temp | ≤28℃ | |||

Keywords:

SiC epitaxial growth furnace | 1600℃ CVD system for semiconductors | Silicon carbide equipment | Graphite muffle CVD furnace | Chemical deposition furnace