Applications:

5G/EV Electronics: Heat spreaders for chips/BMS modules.

Consumer Devices: Flexible graphite sheets for smartphones/tablets.

Energy: Battery thermal interface materials (TIMs)

Next-Gen Thermal Management Materials-Cxinduction™ delivers advanced carbonization and graphitization systems for producing ultra-high-thermal-conductivity POD-resin-derived artificial graphite films/sheet. Our integrated debinding-carbonization process with special Anti pollution pump set, solves the damage caused by acidic substances in the reduction process to the pump set, we also make 3000℃ ultra-High-Temp Graphitization furnace to converts amorphous carbon to highly ordered graphite.

POD Resin Advantages:

↑ Thermal conductivity by 20-30% vs. conventional pitch-based graphite

↓ Dusting (50% reduction in particle shedding)

End Applications

5G/EV Electronics: Heat spreaders for chips/BMS modules

Consumer Devices: Flexible graphite sheets for smartphones/tablets

Energy: Battery thermal interface materials (TIMs)

Key Equipment

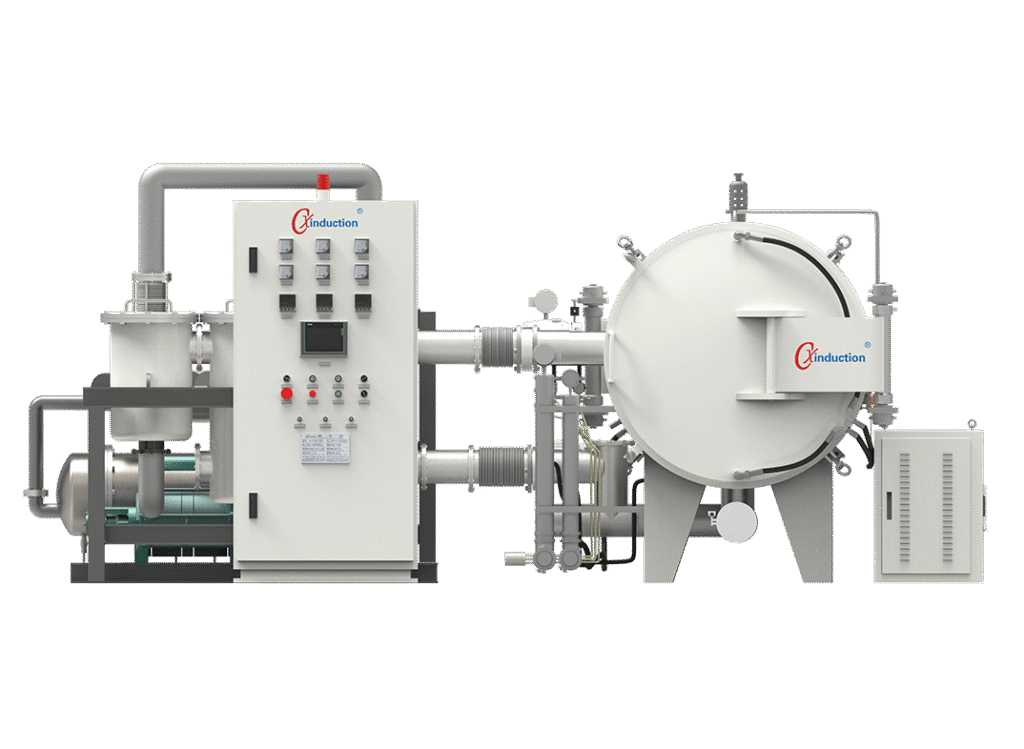

Debinding/Carbonization Furnace of Cxinduction™

Precise pyrolysis of POD films at 800-1200℃(N₂/Ar)

Multi-zone temperature control (±5℃) for uniform carbonization

Tar collection system

3000℃ Ultra-High-Temp Graphitization Furnace of Cxinduction™

Converts amorphous carbon to highly ordered graphite

Achieves >95% crystallinity (critical for anisotropic heat spreaders)

Why Cxinduction™?

Parameter | Conventional Process | Cxinduction™ Solution |

Thermal Conductivity | 400-1000 W/m·K | 800-1900 W/m·K |

Processing Time | 5-7 days | 3-4 days |

Dusting Rate | 3-5% | <1.5% |

Parameters:

Model for POD | CX-CF40/POD | CX-CF50/POD | CX-CF60/POD | CX-CF60/POD |

Heating Method | Graphite Resistance | |||

Control Method | Auto & MAN | |||

Max Work Temp | 1700℃ | |||

Rated power | 75 KW | 90 KW | 120 KW | 160 KW |

Usable Space (mm) W*H*L | 400×400×1200 | 500×500×1500 | 600×600×1800 | 600×600×2000 |

Max. Loading Capacity (L) | 192L | 375L | 648L | 720L |

Temp Uniformity | ±10C (ΔT between 1000C and 2200C) | |||

Max. Heat-up Rate (CEDRT)* | 15℃/min | |||

Ultimate Vacuum (CEDRT)* | 1.2×10-3mbar | |||

Optional High Vacuum | 5×10-5mbar | |||

Pressure Rise | 1.33×10-2mbar/hr | |||

Working Atmosphere | Fine Vacuum (Optional) / Vacuum / Inert Gas (Ar or N2) | |||

Supply Voltage | Can be customized | |||

Cooling Water Pressure | 2bar | |||

Cooling water temp | ≤28℃ | |||