The demand for composite materials is growing, and carbon fiber resin-based composite materials have become the main driving force. It is expected that the market size will reach 305 billion yuan by 2026. Composite materials are widely used in aerospace, missiles, space platforms and launch vehicles, rail transportation, energy and other fields. For example, in the aerospace field, composite materials are used in the manufacture of fuselages and aircraft turbine engines. In the automotive industry, composite materials are used to manufacture car bodies, electrical and thermal insulation components under the hood, etc. In the energy field, composite materials are also increasingly used in wind turbine blades and other fields.

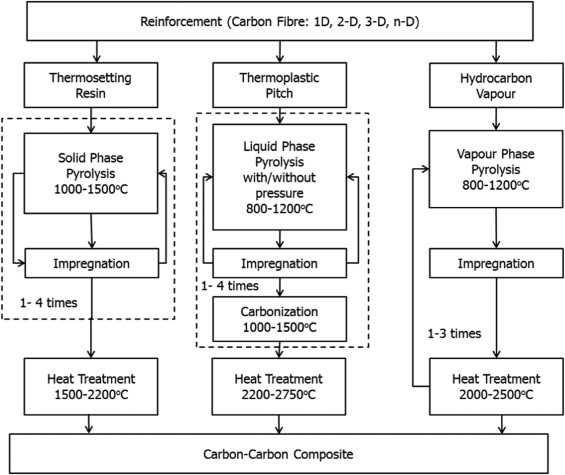

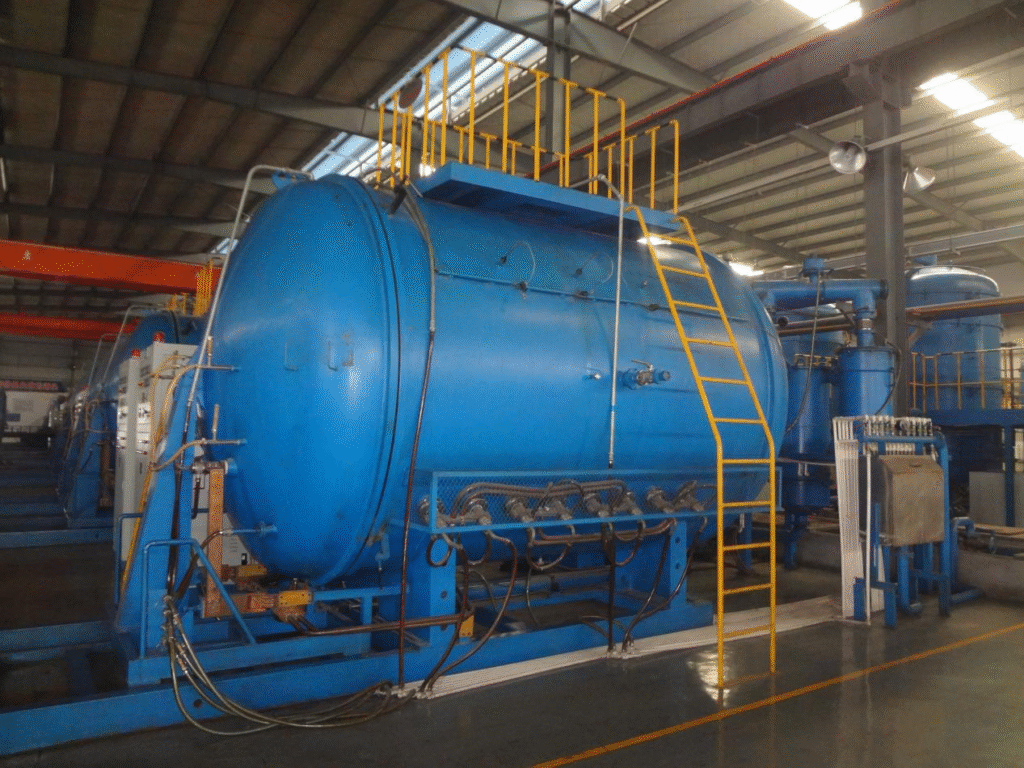

There are two main methods for preparing carbon-carbon composite materials. The preparation process is mainly divided into chemical vapor deposition, liquid phase impregnation and the combined use of these two methods due to different densification processes. The main carbon-carbon composite material companies that have been listed currently all use chemical vapor deposition, which uses methane, propylene and other hydrocarbons to produce carbon deposited in the pores of the carbon fiber preform at high temperature to achieve the densification of the carbon fiber preform; while liquid phase impregnation is to immerse the carbon fiber in a liquid impregnating agent, and use vacuum, pressure and other measures to make the impregnating agent penetrate into the pores of the preform, and then undergo a series of treatment processes such as curing, carbonization, graphitization, and mechanical processing to obtain a carbon-carbon composite material. The carbonization furnace and graphitization furnace designed by Zhuzhou Chenxin have been continuously improved and have won unanimous praise from customers, contributing to the development of China’s carbon-carbon composite materials.

The preparation of carbon-carbon composite materials mainly depends on fiber and matrix materials. Fiber materials usually use polypropylene fiber, polypropylene mesh reinforced fiber, PAN fiber, etc. The matrix material needs to select highly crystalline graphite material, generally using raw materials such as carbide and resin.

There are two molding processes for carbon-carbon composite materials, namely the prepreg method and the blank method. The prepreg method is to use fibers to pre-impregnate the matrix resin, then form it through a compression mold, and then perform a curing and carbonization process. The blank method is to press the carbonized blank through a high-temperature sealed graphite mold, and then perform subsequent carbonization and surface treatment.

Carbonization is an important step in forming carbon-carbon composite materials. Carbonization is divided into two methods: pyrolysis carbonization and chemical vapor carbonization. Pyrolysis carbonization is to carbonize the formed composite material at high temperature, while chemical vapor carbonization is to convert the matrix material into carbon material through gas phase reaction at high temperature. Graphitization is to convert the carbide of the composite material into graphite through further high-temperature treatment to improve its mechanical strength and thermal conductivity.

In the process of surface treatment of carbon-carbon composite materials, chemical treatment and physical treatment are commonly used. Chemical treatment mainly uses chemical methods such as oxidation, chlorination, and fluorination for treatment, while physical treatment uses mechanical grinding, cutting, polishing, and other methods for treatment.

CX-CF-Lab It is a vertical top-loading graphite resistance heating furnace. It has a compact and integrated design, with a maximum temperature of up to 2200℃.

CX-GF-Lab is vertical top loading induction heating furnace.Compact and integrated design which is ideal for various research applications and new materials development.

CX-GF series are vertical top and loading batch type induction heating furnaces, excellent temp uniformity which is ideal for synthetic graphite sheet type materials.