Introduction

High thermal conductivity artificial graphite sheets are critical materials in modern electronics, energy storage, and thermal management systems. These sheets are widely used in smartphones, laptops, electric vehicles (EVs), and LED lighting due to their exceptional heat dissipation, lightweight properties, and flexibility. To achieve optimal performance, graphite sheets must undergo precise carbonization and graphitization heat treatment processes. Cxinduction™, a leading global supplier of high-temperature equipment, provides the industry’s most advanced dewaxing carbonization furnaces and ultra-high-temperature graphitization furnaces, which have been successfully deployed in hundreds of production lines worldwide.

Key Heat Treatment Processes for Artificial Graphite Sheets

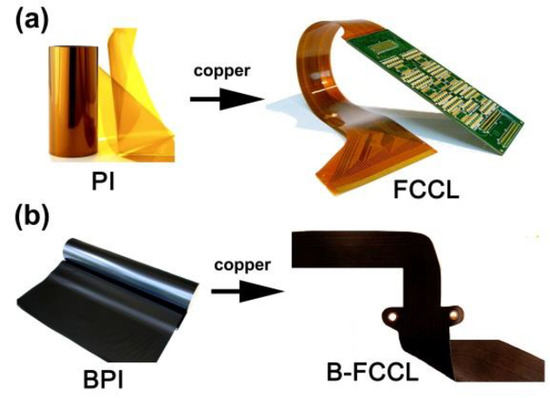

Purpose: Removes volatile impurities and converts polymer-based precursors (e.g., polyimide films) into carbon-rich structures.

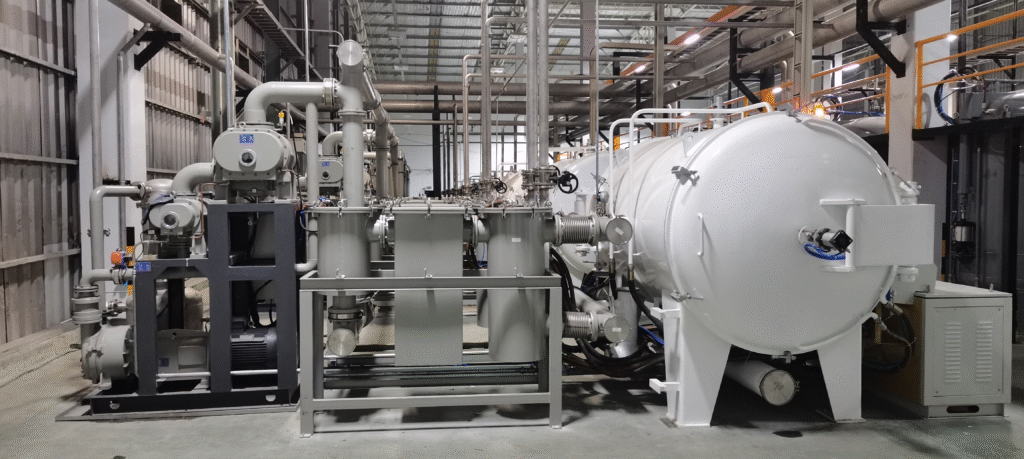

Equipment: Cxinduction™ Dewaxing Carbonization Furnace

Temperature Range: 800–1900℃ (precise control within ±1℃).

Atmosphere: Vacuum

Uniform Heating: Multi-zone temperature control ensures consistent carbonization.

Filter: Three-stage filtration system

Challenges:

Avoiding cracks or warping due to uneven heating.

Ensuring complete impurity removal for high-purity carbon structures.

Purpose: Converts amorphous carbon into highly ordered graphite crystals, enhancing thermal conductivity (up to 1500–2000 W/m·K).

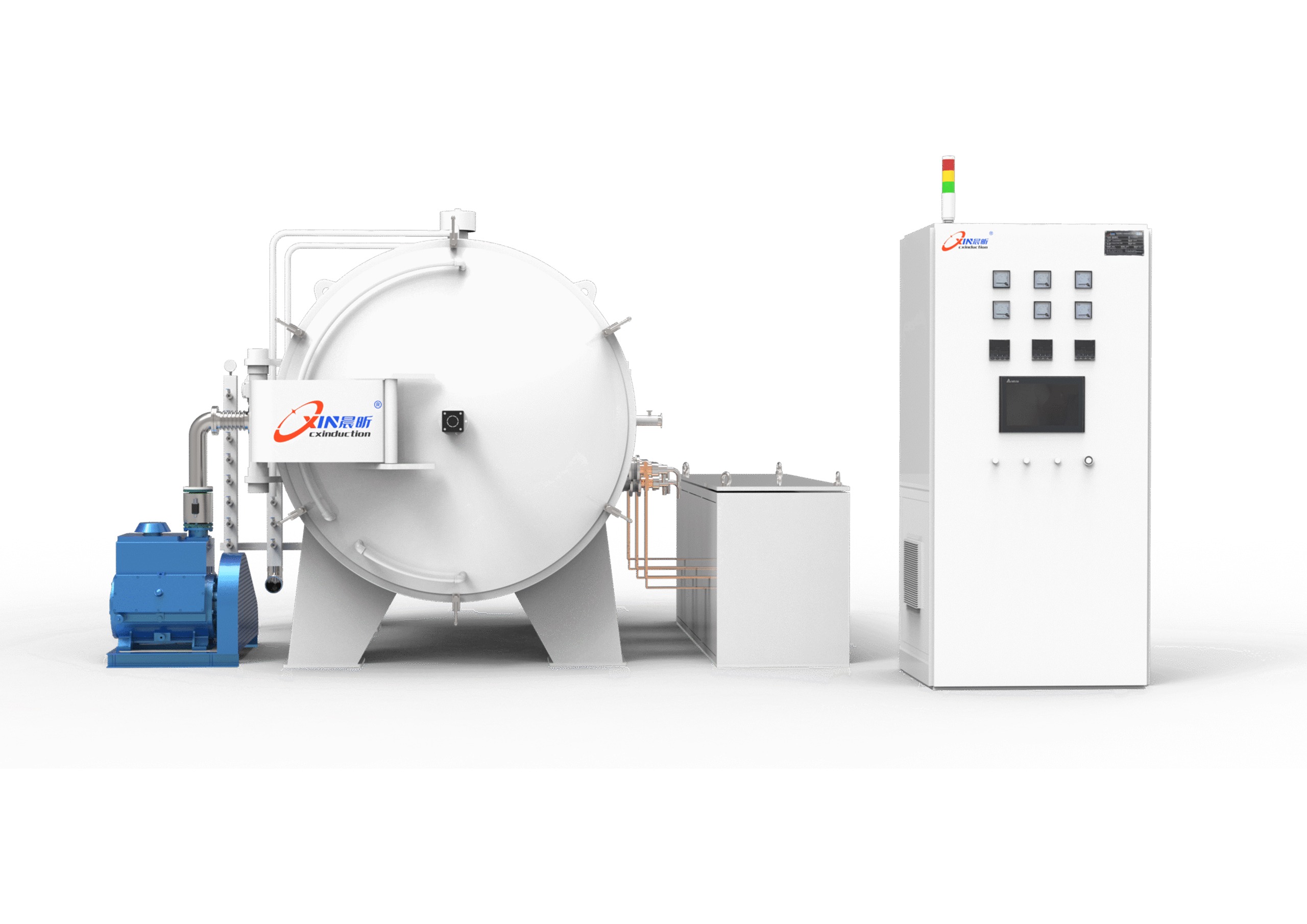

Equipment: Cxinduction™ Ultra-High-Temperature Graphitization Furnace

Temperature Range: 2500–3000℃ (with ±5℃ uniformity).

Heating Elements: High-purity graphite for long lifespan.

Vacuum or Inert Gas: Prevents contamination and ensures high crystallinity.

Challenges:

Maintaining extreme temperatures without degrading furnace components.

Achieving uniform graphitization for consistent thermal performance.

Why Choose Cxinduction’s Heat Treatment Equipment?

Fast heating/cooling rates (programmable for different material grades).

Advanced insulation materials reduce energy consumption by 20–30%.

Modular design allows easy maintenance and long-term reliability.

PLC-controlled process with real-time monitoring.

Data logging ensures batch-to-batch consistency.

Hundreds of installed units worldwide – trusted by top graphite sheet manufacturers.

24/7 technical support for uninterrupted production.

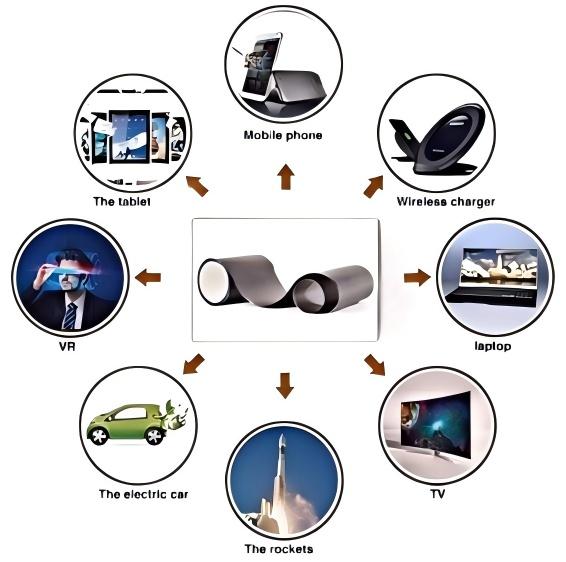

Applications of Heat-Treated Graphite Sheets

Smartphones & Tablets: Heat spreaders for CPUs and batteries.

Laptops: Thermal management in high-performance GPUs.

Battery Packs: Prevents overheating in Li-ion batteries.

Power Electronics: Cooling for inverters and motors.

Heat sinks for high-brightness LEDs.

5G Base Stations: Thermal interface materials (TIMs).

Satellite components requiring lightweight, high-thermal-conductivity materials.

Success Stories: Global Recognition

Cxinduction’s carbonization and graphitization furnaces are used by leading graphite sheet suppliers in China, Japan, South Korea,etc, enabling:

✔ Higher thermal conductivity (20–30% improvement vs. conventional furnaces).

✔ Lower energy costs due to optimized heating efficiency.

✔ Zero warping/cracking – near-perfect yield rates.

Conclusion

The production of high-performance artificial graphite sheets relies on precision heat treatment with advanced carbonization and graphitization furnaces. Cxinduction’s dewaxing carbonization furnace and ultra-high-temperature graphitization furnace provide unmatched temperature control, energy efficiency, and process repeatability, making them the preferred choice for global manufacturers.

Advanced cvD solutions for Sic Semiconductor Manufacturing presents a 1600'C Multi-Atmosphere CvD Furnace specifically engineered

CX-GF-Lab is vertical top loading induction heating furnace.Compact and integrated design which is ideal for various research applications and new materials development.

Precision CvD system for High-Quality Graphene Production presents a 1600'c Multi-Atmosphere cvD furnaceengineered for reliable