Description:

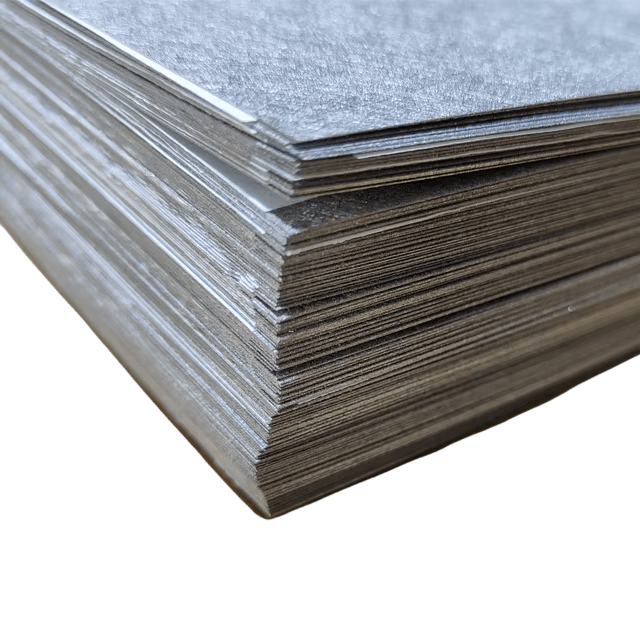

Titanium Fiber Felt is a porous material made by sintering fine titanium fibers into a felt-like, mesh structure. It combines the excellent corrosion resistance and lightweight properties of titanium with high porosity and surface area.

Get a Free Sample to Start!

Typical applications of Titanium Fiber Felt:

It is widely used in filtration, electrode and catalyst supports, biomedical implants, thermal management, and energy storage devices like fuel cells and batteries.

Titanium Fiber Felt Applications

Filtration:Used as a high-efficiency filter medium for gas and liquid filtration in corrosive or high-temperature environments, such as in chemical, pharmaceutical, and food industries.

Electrodes in Electrochemical Applications:Serves as a current collector or electrode material in fuel cells, electrolyzers, and batteries due to its high conductivity and corrosion resistance.

Advantages of Titanium Fiber Felt

Excellent corrosion resistance

High porosity and large surface area

Good electrical and thermal conductivity

Lightweight and flexible structure

Biocompatible for medical applications

Features | Titanium fiber felt |

Structure | Sintered, randomly oriented titanium fibers |

Porosity (customized) | 50-90%, elongated, directional pores |

Thickness (customized) | 0.2mm-3.5mm |

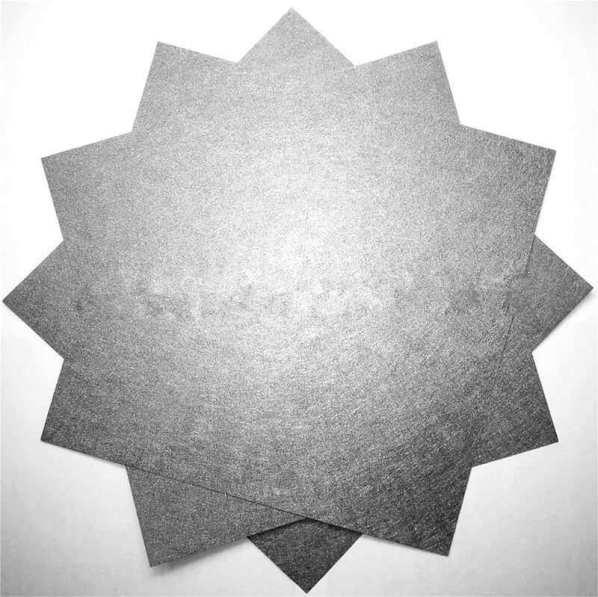

Size (customized) | 50x50mm, 100x100mm, 200x200mm, 300x300mm… |

Mechanical Properties | Flexible, compressible |

Electrical Conductivity | High, due to fiber alignment |

Thermal Conductivity | Relatively high |

Surface Area | High, due to fiber mesh |

Applications | Electrodes, filtration, catalyst support |

Typical Use Cases | Fuel cells, flow batteries, chemical reactors |

FAQ:

1.Q: What’s the standard of Titanium fiber felt?

A: Benchmarking Japanese process standards, we got excellent feedback from our customers.

2. Q: Why choose titanium fiber felt over carbon felt for electrolyzers?

A: Titanium fiber felt is oxidization-resistant, making it ideal for the oxygen-evolving anode side, where carbon felt degrades into CO2/carbonates. It ensures long-term stability in acidic/alkaline environments, unlike carbon materials.

3. Q: Does titanium fiber felt require a coating for optimal performance?

A: While bare titanium works, a platinum (Pt) coating significantly enhances conductivity and reduces interfacial resistance, improving electrolyzer efficiency. Other coatings (e.g., IrO2) can also be applied for specific needs.

4. Q: What thickness and porosity options are available?

A: Standard thickness: 0.2-3.5 mm (customizable). Porosity ranges from 50-90%-higher porosity improves gas diffusion, while lower porosity increases mechanical strength.

5. Q: Can you provide custom sizes or shapes for stack integration?

A: Absolutely! We supply:

Standard sheets (e.g., 100 × 100 mm to 1 × 1 m).

Custom-cut shapes (circles, trapezoids for bipolar plates).

Integrated GDL/catalyst layers (pre-coated with IrO2, etc.).

6. Q: MOQ?

A: Low minimum order quantities for R&D; bulk discounts for production.

7. Q: Lead Time?

A: 2-3weeks (stock items ship in 5 days).