Introduction

Precision ceramic sintering is a critical process in manufacturing high-performance ceramic components used in industries such as electronics, aerospace, defense, and medical devices. Materials like silicon carbide (SiC), boron carbide (B4C), aluminum nitride (AlN), and tantalum capacitor ceramics require precise sintering conditions to achieve optimal density, mechanical strength, and thermal/electrical properties. Cxinduction™ vacuum sintering furnaces provide accurate temperature control (±1℃) and excellent Temp uniformity (≤±10℃), ensuring consistent product quality that meets global standards.

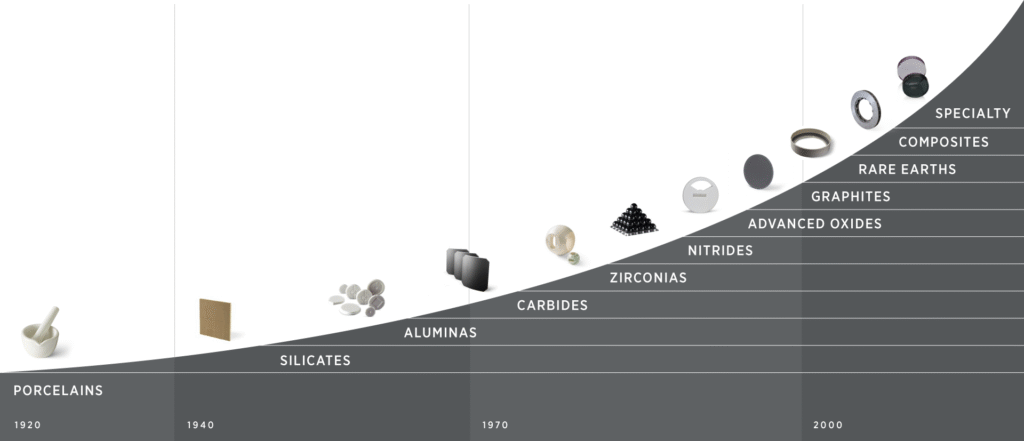

Ceramic Materials & Their Sintering Requirements

Applications: High-temperature components, semiconductor equipment, armor plates.

Sintering Process: Typically sintered at 1900–2200°C under vacuum or inert gas.

Challenges: Low self-diffusion coefficient requires precise heating rates and dwell times.

Applications: Nuclear shielding, bulletproof armor, abrasive materials.

Sintering Process: Sintered at 2000–2200℃, often with sintering aids (e.g., carbon).

Challenges: High hardness makes densification difficult; temperature uniformity is critical.

Applications: Heat sinks, LED substrates, high-power electronics.

Sintering Process: Sintered at 1700–1900℃ in nitrogen atmosphere.

Challenges: Oxygen contamination must be minimized to ensure thermal conductivity.

Applications: High-capacitance electronic components.

Sintering Process: Low-temperature sintering (1300–1500℃) with fine vacuum, metal shields

Challenges: Requires strict atmosphere control to prevent oxidation.

Critical factors in Ceramic Sintering

Precision heating (±1℃) ensures phase stability and avoids cracking.

Multi-zone heating systems (like those in Cxinduction™ furnaces) eliminate hot/cold spots.

Vacuum sintering prevents oxidation (critical for SiC, AlN).

Gas pressure sintering (GPS) improves densification for B4C

Too fast → thermal stress → microcracks.

Too slow → excessive grain growth → weakened mechanical properties.

Carbon for B₄C, Y₂O₃ for AlN – must be uniformly mixed and burnout-controlled.

Why Choose Cxinduction™ Vacuum Sintering Furnaces?

±1°C control with advanced PID algorithms.

Uniformity within ≤±10℃ across the entire hot zone.

High vacuum (10-4Pa is optional) for oxidation-sensitive materials.

Programmable gas flow (N₂, Ar) for reactive sintering.

Graphite/CFC heaters for high temperatures (up to 2400°C).

Multi-layer insulation for energy efficiency and thermal stability.

Touchscreen HMI with preset programs for different ceramics.

Data logging & remote monitoring for repeatability.

Success Stories: Global Recognition

Cxinduction™ sintering solutions have been widely adopted by client both home and abroad

SiC ceramic plates (used in semiconductor wafer handling).

B4C armor tiles (military applications).

AlN heat spreaders (high-power electronics).

Tantalum capacitor dielectrics (consumer electronics).

Clients consistently praise:

✔ Repeatable quality (batch-to-batch consistency).

✔ Reduced defect rates (near-zero porosity).

✔ Energy-efficient operation (lower production costs).

Conclusion

Precision ceramic sintering demands exact temperature control, atmosphere management, and process repeatability – all of which are delivered by Cxinduction™ advanced vacuum sintering furnaces. Whether for SiC, B4C, AlN, or tantalum ceramics, our technology ensures high density, superior mechanical properties, and flawless performance.

Sintering is a thermal process that causes the powdered materials, typically metals or ceramics, to bond without fully melting, resulting in a solid piece with enhanced strength, durability, and density

Advanced ceramic materials with good wear resistance, thermal conductivity, oxidation resistance, and excellent high-temperature mechanical properties

Silicon carbide ceramic materials with good wear resistance, thermal conductivity, oxidation resistance

CXinduction® vacuum sintering furnaces uses graphite as heating elements.It is specially used to sinter carbides, nitrides and oxide ceramics into products in a vacuum or protective atmosphere.

Aluminium nitride (AlN) is a high-performance ceramic that is characterised by its exceptional thermal conductivity and electrical insulation.

Cemented carbide is a tool material that has all properties necessary for cutting tools, including hardness and strength.

1500℃ Vacuum Sintering Furnace is engineered for high-density tungsten carbide (WC) sintering, utilizing a multi-layer molybdenum-tungsten (Mo-W) hot zone to ensure uniform heating and prevent contamination.

The 1700℃ Tantalum Capacitor Vacuum Sintering Furnace by Cxinduction™ is designed for high-temperature sintering of refractory metals (W, Mo, Ta, Nb) and oxide ceramics in an ultra-clean,

Advanced ceramic materials with good wear resistance, thermalconductivity, oxidation resistance, and excellent high-temperaturemechanical properties