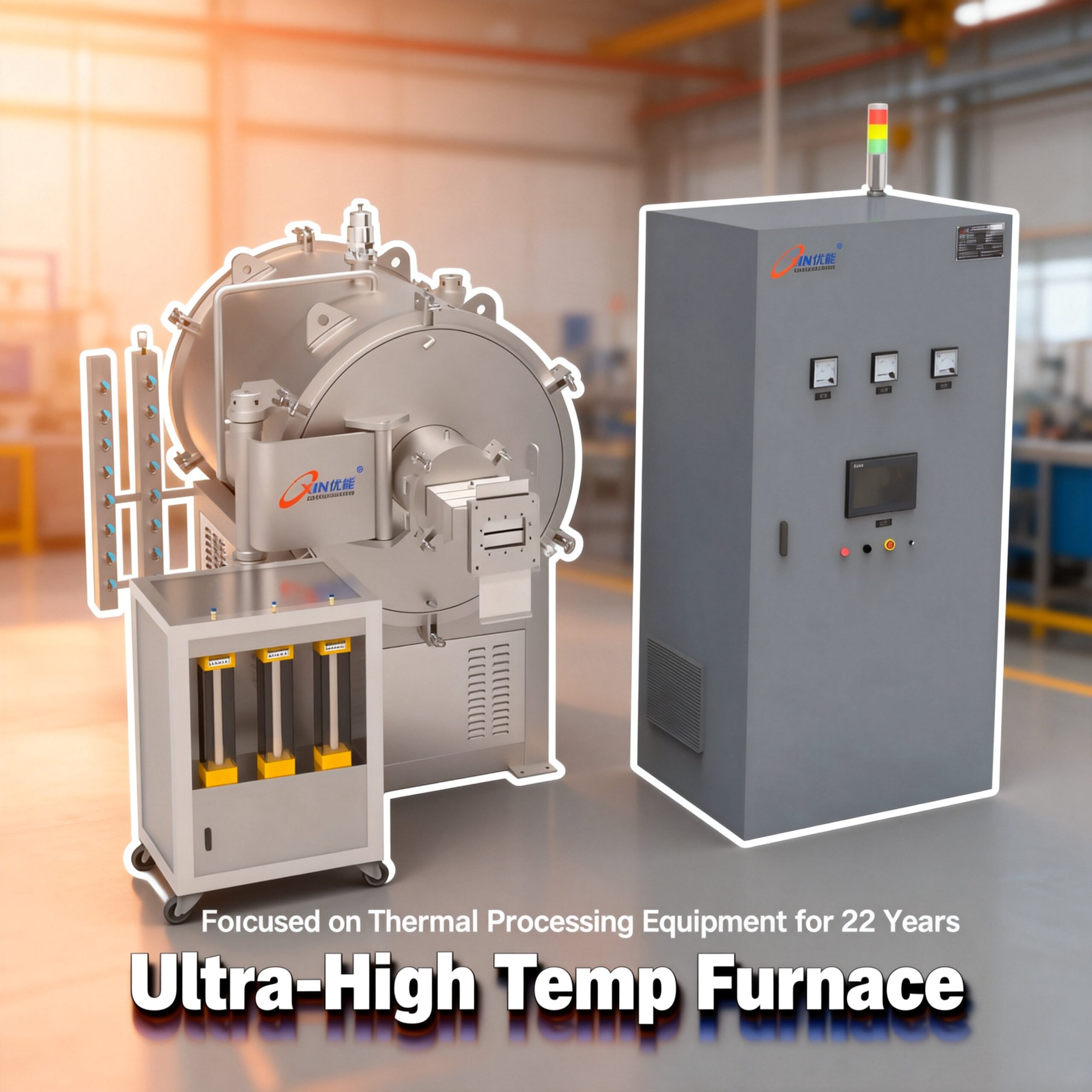

2200℃ Laboratory Carbonization Furnaces

CX-CF-Lab It is a vertical top-loading graphite resistance heating furnace. It has a compact and integrated design, with a maximum temperature of up to 2200℃.

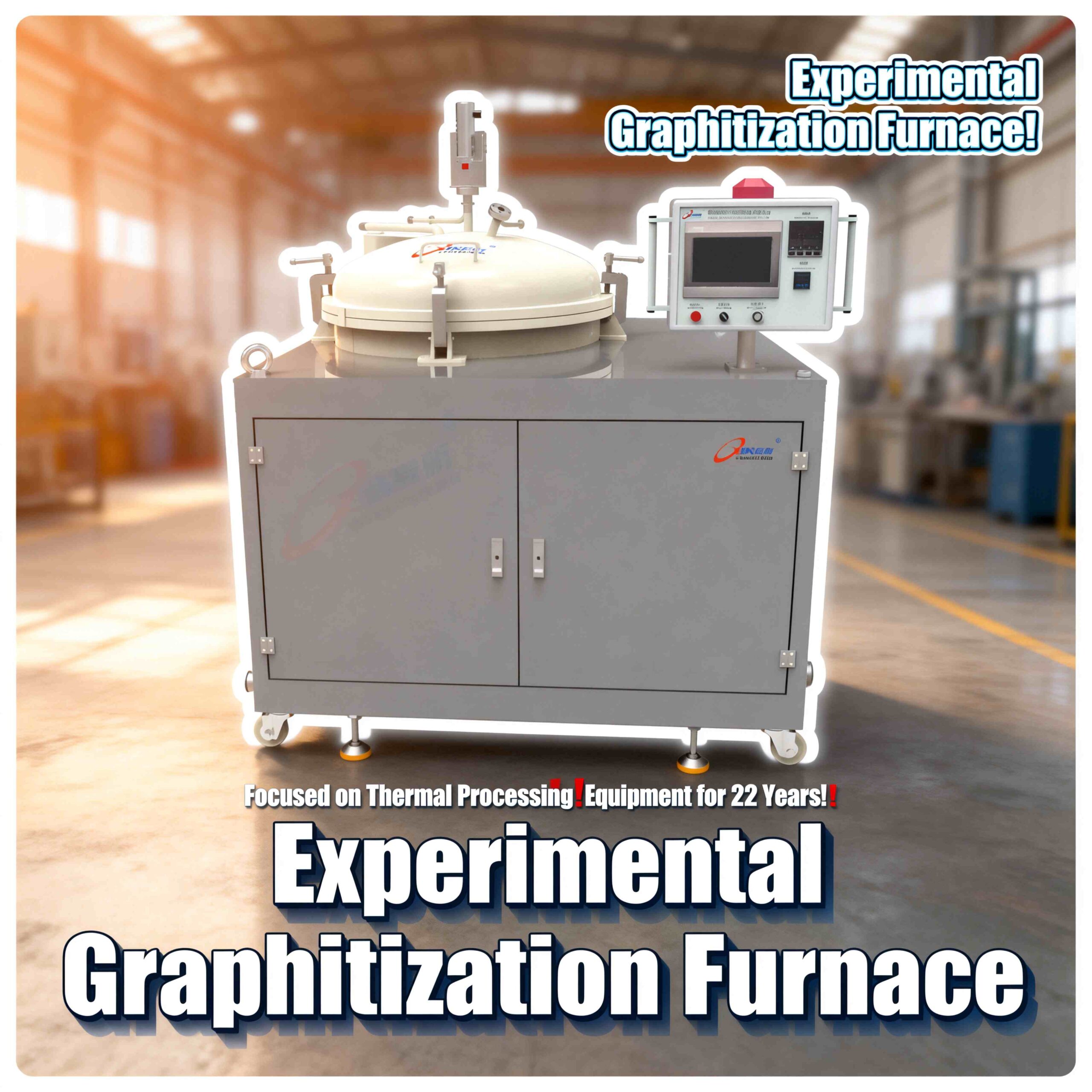

3000℃Laboratory Induction Furnace

CX-GF-Lab is vertical top loading induction heating furnace.Compact and integrated design which is ideal for various research applications and new materials development.

Argon purifier

Argon gas purifier is an essential device used to remove impurities

Cooling Equipment

Closed cooling towers are smaller, cheaper, but with a larger growth rate...

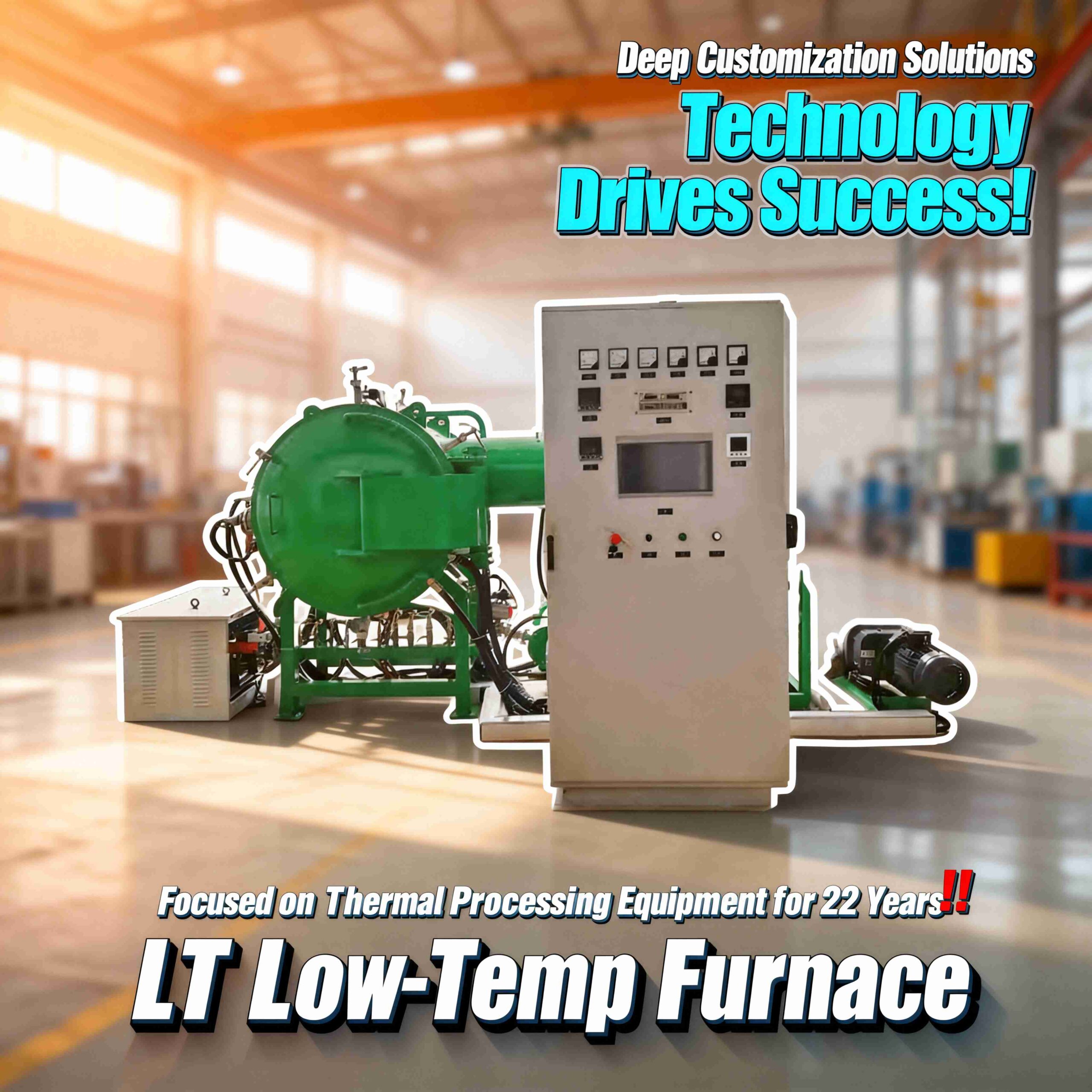

800-1600℃Continuous Carbonization Furnace for Carbon Fiber & SiC Fiber

Continuous Carbonization Furnace delivers industry-leading performance for processing :Carbon paper/cloth,PAN-based carbon fibers

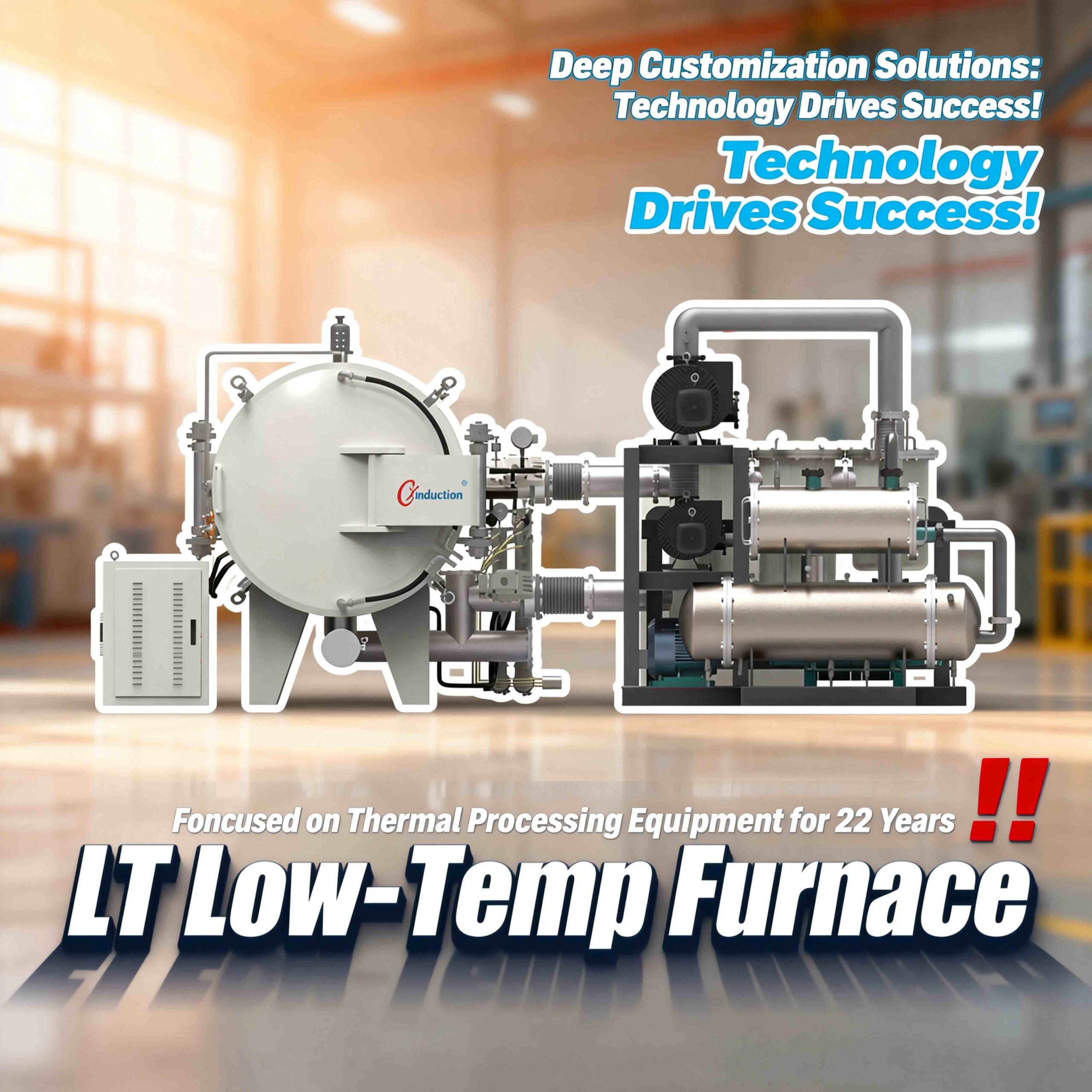

1000-1800℃ Carbon-Carbon & Carbon-Ceramic CVD Furnace

Carbon-Carbon/Carbon-Ceramic CVD Furnace enables precision chemical vapor deposition (CVD) to produce ultra-dense C/C and C/SiC composites...

1500°C Tungsten Carbide Vacuum Sintering Furnace

1500℃ Vacuum Sintering Furnace is engineered for high-density tungsten carbide (WC) sintering, utilizing a multi-layer molybdenum-tungsten (Mo-W) hot zone to ensure uniform heating and prevent contamination.

1600℃ Graphene Sheet Carbonization Furnace

Advanced Carbonization Solutions for Thermal Materials specializes in high-performance carbonization and graphitization systems

1600℃ Silicon Carbide (SiC) Epitaxial Substrate CVD Furnace

Advanced CVD Solutions for SiC Semiconductor Manufacturing presents a 1600℃ Multi-Atmosphere CVD Furnace specifically engineered

1600℃ Single-Layer Graphene Growth CVD Furnace

Precision CVD System for High-Quality Graphene Production presents a 1600℃ Multi-Atmosphere CVD Furnace engineered for reliable

1700℃ Biomass Carbonization Furnace for High-Temperature Processing

The 1700℃ High-Temperature Carbonization Furnace by Cxinduction™ is an advanced thermal processing system designed to convert organic materials into carbon-rich substances under vacuum or controlled atmosphere.

1700℃ Tantalum Capacitor Vacuum Sintering Furnace

The 1700℃ Tantalum Capacitor Vacuum Sintering Furnace by Cxinduction™ is designed for high-temperature sintering of refractory metals (W, Mo, Ta, Nb) and oxide ceramics in an ultra-clean,

1700℃ POD Resin Film Carbonization Solutions

Next-Gen Thermal Management Materials delivers advanced carbonization and graphitization systems for producing ultra-high-thermal-conductivity POD-resin-derived artificial graphite films/sheet.

1900℃ Vacuum Sintering furnace for carbides, nitrides and oxide ceramics

CXinduction® vacuum sintering furnaces uses graphite as heating elements.It is specially used to sinter carbides, nitrides and oxide ceramics into products in a vacuum or protective atmosphere.

2000℃ Sintering furnace for Aluminum nitride ceramics

Aluminum nitride (AlN) is a high-performance ceramic, characterized by excellent thermal conductivity and electrical insulation properties.

2000℃ Vacuum Dewax Sintering furnace for Cemented Carbide

Cemented carbide is a kind of tool material that possesses all the characteristics required for cutting tools, including hardness and strength.

2000℃ Sintering furnace for metal powder

Sintering is a thermal process that causes the powdered materials, typically metals or ceramics, to bond without fully melting, resulting in a solid piece with enhanced strength, durability, and density

2300℃ Debinding Sintering furnace for Precision ceramics

Advanced ceramic materials with good wear resistance, thermal conductivity, oxidation resistance, and excellent high-temperature mechanical properties

2400℃ Sintering furnace for Silicon carbide

Silicon carbide ceramic materials with good wear resistance, thermal conductivity, oxidation resistance

2500℃ Sic Recrystallization Sintering Furnace

Silicon carbide ceramic materials with good wear resistance, thermal conductivity, oxidation resistance, and excellent high-temperature mechanical properties,

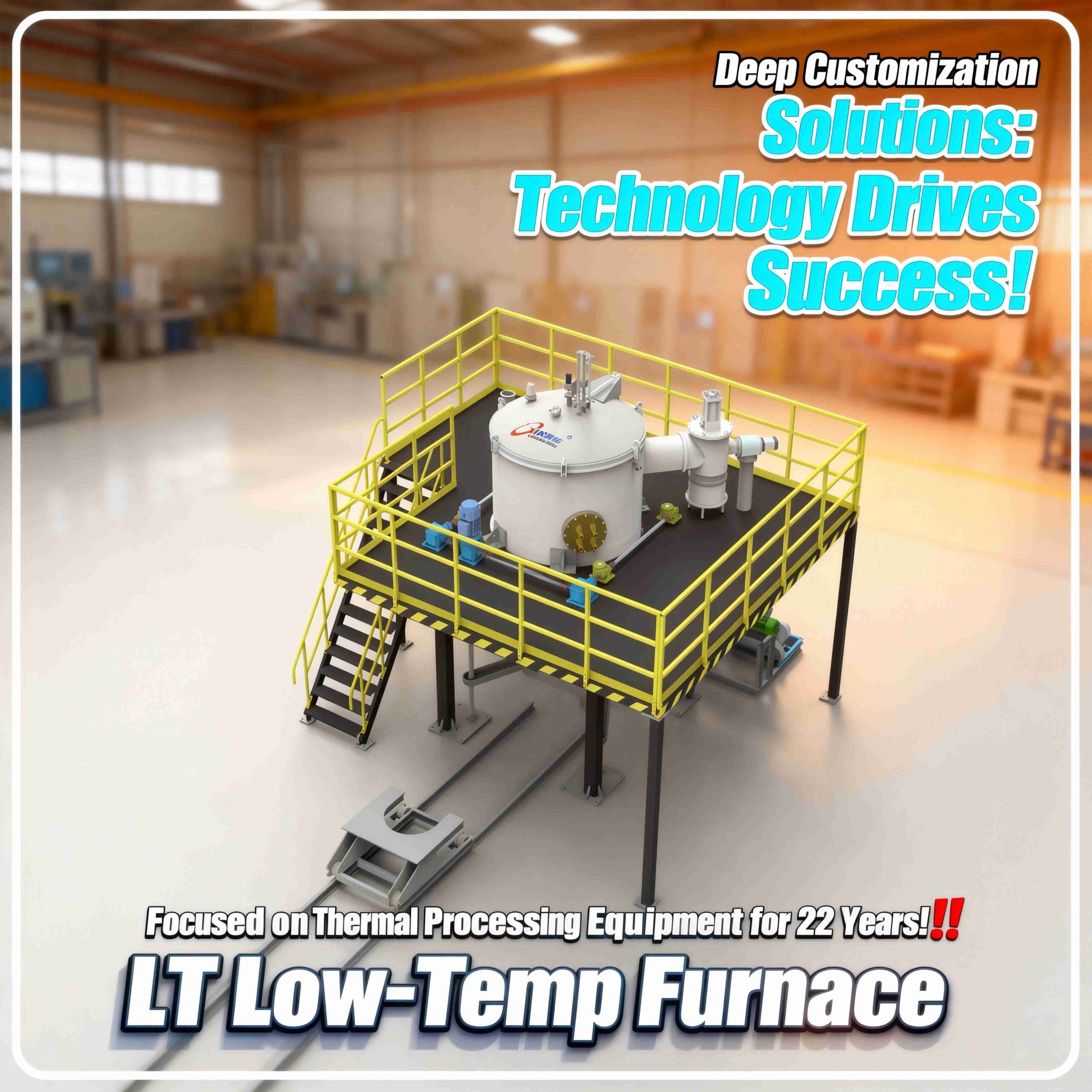

2700℃ Carbon fiber Carbon paper Silicon carbide fiber Graphitization furnace

CNT can be single-, double-, and multi-walled. CNT have unique mechanical, electrical, and optical properties, all of which have been extensively studied.

2700°C graphitization furnace for Carbon Carbon composites(CC/ CFC) Product Introduction

CX-GF series are vertical top and loading batch type induction heating furnaces, excellent temp uniformity which is ideal for synthetic graphite sheet type materials.

2800℃ graphitization furnace for CNT/VGCF purification

CNT can be single-, double-, and multi-walled. CNT have unique mechanical, electrical, and optical properties,

2900℃ battery anode purification graphitization furnace

CX-GF series are vertical top and loading batch type induction heating furnaces, excellent temp uniformity which is ideal for powder type materials.

3000℃ graphite sheet graphitization furnace

CX-GF series are vertical top and loading batch type induction heating furnaces, excellent temp uniformity which is ideal for synthetic graphite sheet type materials.

Titanium Fiber Felt for Electroyzer Hydrogen

Titanium Fiber Felt is a porous material made by sintering fine titanium fibers into a felt-like, mesh structure. It combines the excellent corrosion resistance and lightweight properties of titanium with high porosity and surface area.

Carbon cloth, a new choice for high-end materials

Carbon cloth, with its all-round characteristics of "high strength, high modulus, resistance to high and low temperatures, and excellent electrical and thermal conductivity", redefines the application boundaries of high-end materials.

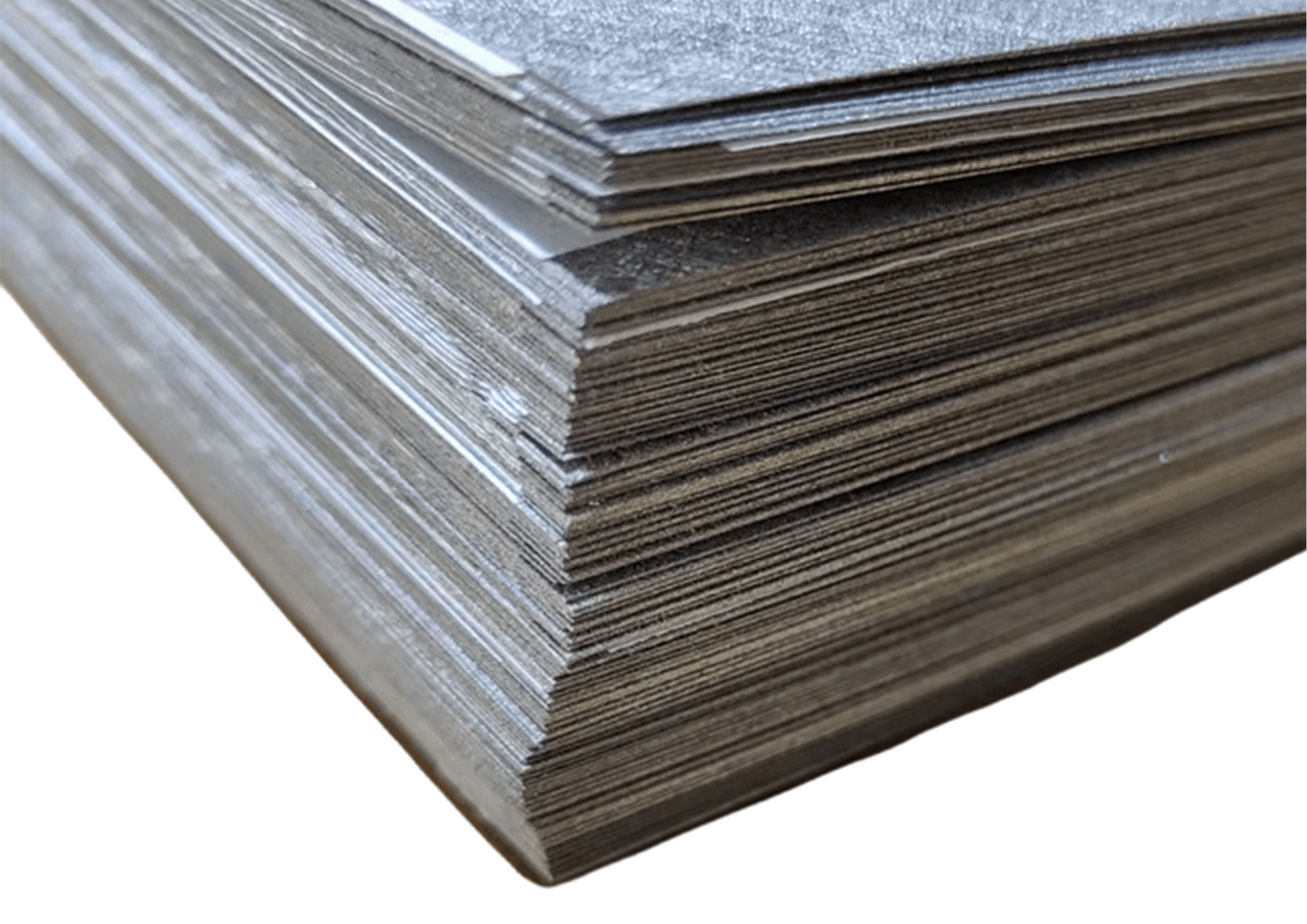

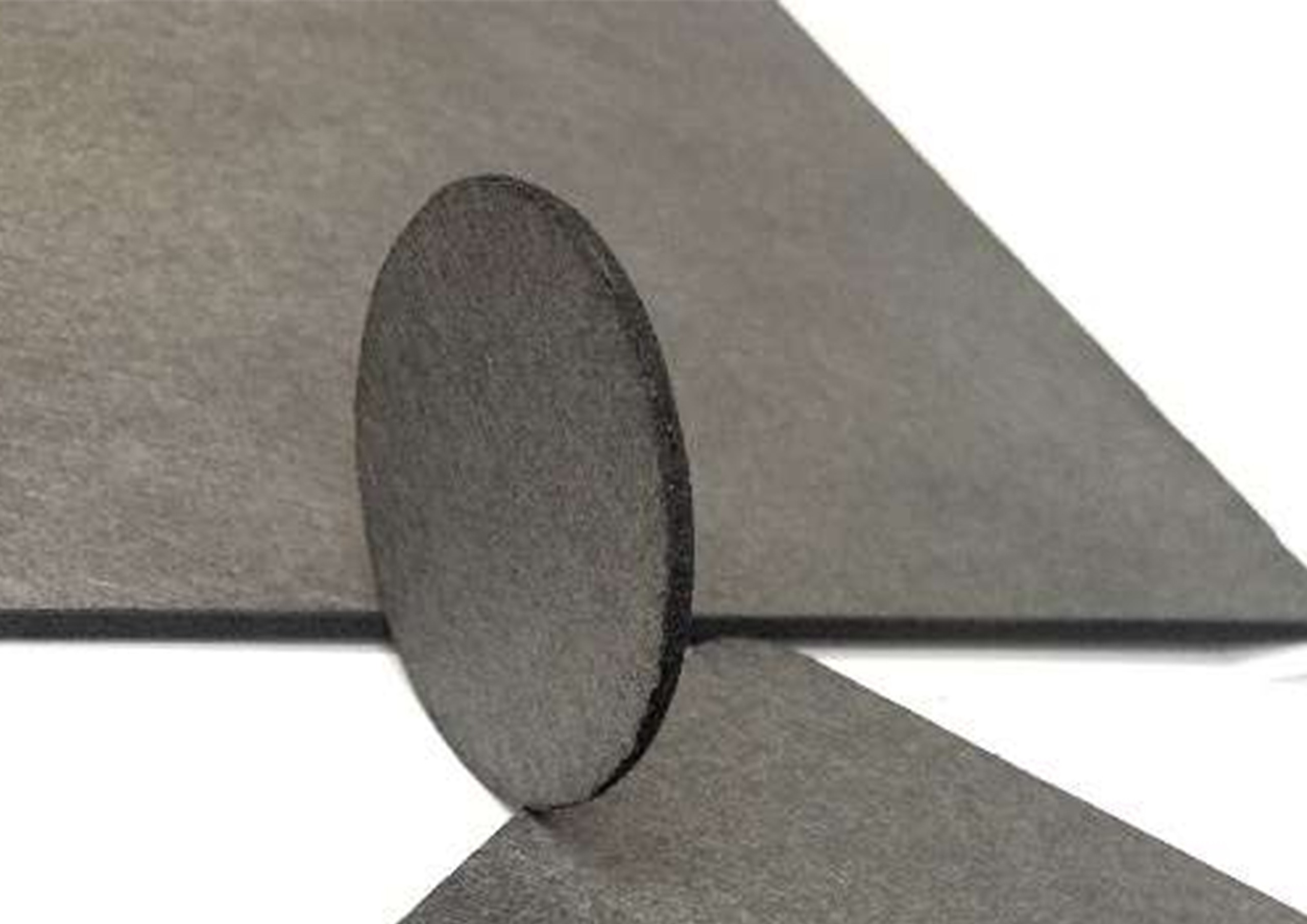

Carbon Paper: The Invisible Bridge of Energy Conversion

Carbon paper, with the advantages of "ultra-thin and dense, uniformly conductive, and low contact resistance", has become an "invisible bridge" for efficient energy conversion.