Application:

Cemented carbide is a tool material that has all properties necessary for cutting tools, including hardness and strength. Cemented carbide is made by powdered tungsten carbide (WC), mixing cobalt (Co) powder in it as a binder, and sintering the mixture. The metal matrix, or binder, is usually cobalt, but nickel and chromium are also used, to form hard metal, carbide powders are milled with the metal binder to obtain a powder that is consolidated through pressing, extrusion or Metal Injection Moulding (MIM), followed by sintering.

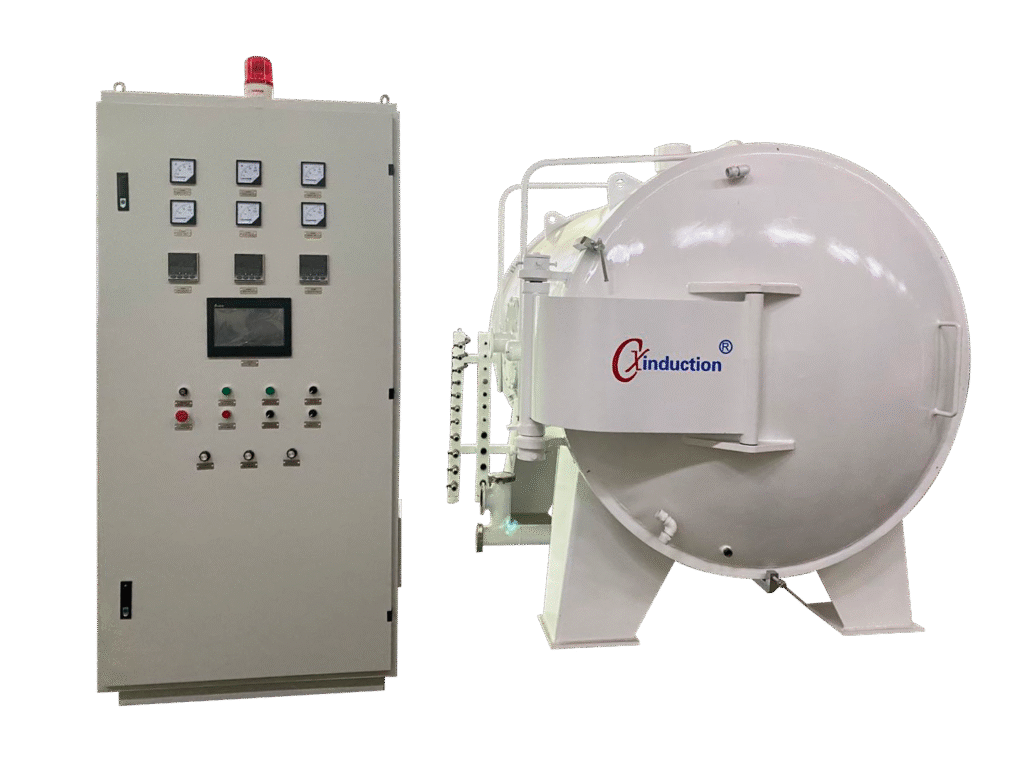

CXinduction® high temp sintering furnaces, with cooled dewaxing design, accurate temp control, ideal for dewaxing and sintering cemented carbides.

Application:

Welcome to send inquiry for your material!

Features:

Parameters:

Model | SJ30/60C-1 | SJ40/80C-1 | SJ50/120C-1 | SJ60/150C-1 | SJ70/150C-1 |

Heating Method | Graphite Resistance heating Method | ||||

Control Method | Auto & Semi-Auto & MAN | ||||

Max Design Temperature | 2000C | ||||

Max Work Temperature | 1900C | ||||

Work size (mm) W×H×L | 300×300×600 | 400×400×800 | 500×500×1200 | 600×600×1500 | 700×700×1500 |

Max. Loading Capacity | 54L | 128L | 300L | 540L | 735L |

Temp Uniformity | ±10C (ΔT between 1000C and 1700C) | ||||

Max. Heat-up Rate | 15°C/min (RT~1500°C), 10°C/min (1500°C~2500°C), 5°C/min (2500°C~3000°C) | ||||

Heating Power | 50 KW | 120 KW | 200 KW | 220KW | 300 KW |

Vacuum (CEDRT)* | 5pa(empty, cold, tidy condition), Can be customized | ||||

Working Atmosphere | Vacuum / Inert Gas (Ar) Vacuum is only permitted below 2200C | ||||

Supply Voltage | 3P, 380V, 400V, 415V, 480V can be customized | ||||

Cooling Water Pressure | 1.5-2.5bar | ||||