Round and square graphite crucibles

Induction coil

Fast heating

What factors affect the temperature uniformity of graphitization furnace?

Graphitization furnace is a ultra-high temp furnaces used in graphitization process, temperature uniformity directly affects product quality. Factors affecting the temperature uniformity of graphitization furnace mainly include the following aspects.

First, furnace design. Furnace design includes furnace shape, size, layout of heating elements, etc. The furnace shape should be reasonable to ensure that the atmosphere flow evenly; the furnace size should match the product to be processed to avoid uneven temperature caused by Unreasonable size. The layout of heating elements should be determined according to the product properties and heating requirements to ensure uniform temperature distribution in the furnace.

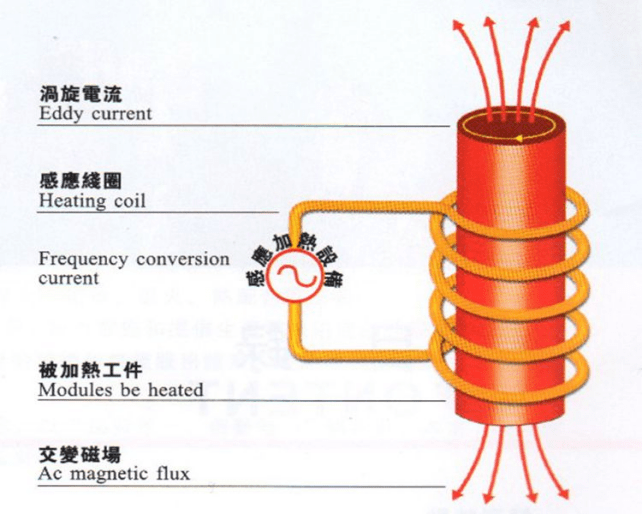

Secondly, the heating method has a greater impact on the temperature uniformity and Max Temp. The graphitization furnace adopts medium frequency induction radiation heating, which has higher heating efficiency and faster heating speed and can reach 3000C easily. Compared with the resistance heating method, it is easier to maintain and has a longer service life.